Case Study: Pipe Freeze Operation for Government Agency

PFS Nitrogen Services, sister company of the industry leading N2 Solutions Company, is renowned for its expertise in nitrogen-propelled pigging...

PFS Nitrogen Services, an N2 Solutions company, formulated the project execution plan, provided on-site project management, acquired cleaning pig(s), supplied backpressure control system, executed pipeline pigging, and deployed their nitrogen field proficiency for one of the largest energy infrastructure companies in North America. This integrated strategy guaranteed the pipeline's successful inspection, playing a pivotal role in the project's overall success.

With careful planning and flawless execution, PFS overcame obstacles and achieved exceptional outcomes, establishing a benchmark for efficiency and dependability in nitrogen services. Explore the reasons why PFS and N2 Solutions are the top choice for intricate projects.

New Jersey

OD: 12.75”

Length: 1.9mi

WT: 0.25"

MOP: 740psi

Product: Line is under a 10psi nitrogen blanket

The client reached out to PFS to plan and conduct an ILI assessment of an out of service liquid pipeline system, aiming to assess its condition before initiating any restoration efforts following seven years of inactivity.

Our pipeline pigging Subject Matter Expert (SME) consulted with the client on-site to survey the work areas, pinpoint any obstacles, and worked together, along with the inspection tool vendors, to devise the execution plan for the successful pipeline inspection.

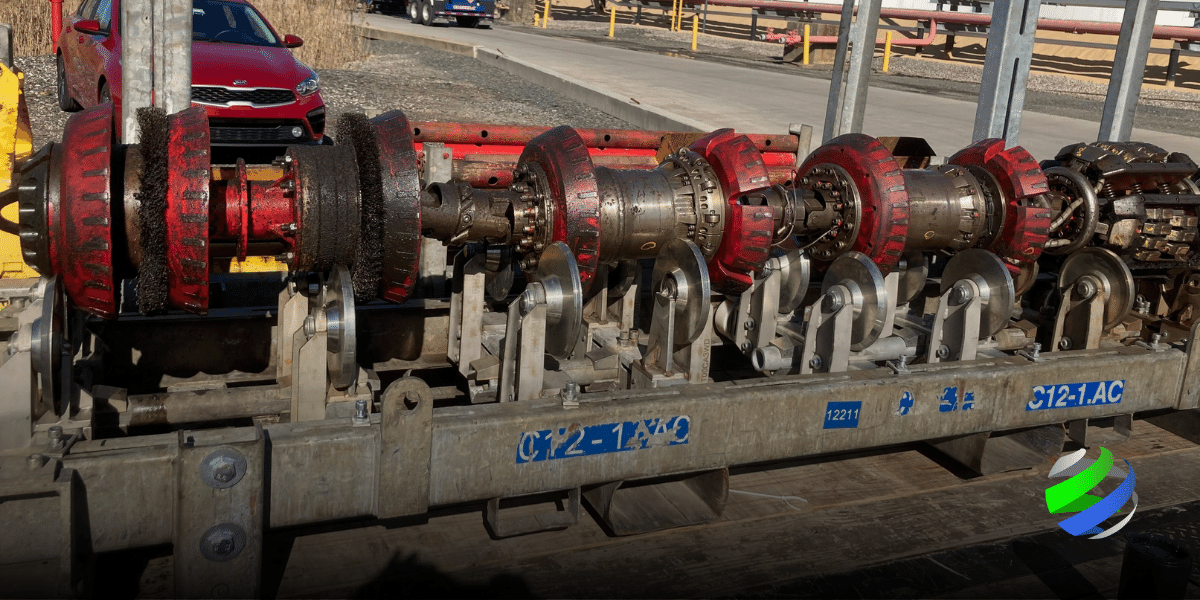

The approach entailed deploying an initial foam disc pig to confirm the line's pigging capability and evaluate the pipeline's cleanliness to determine if additional cleaning was necessary. Subsequently, a gauge pig and two distinct smart tool runs were propelled through the pipeline.

PFS can help with all aspects of pigging. Keep reading to learn more about the pigging products and services we offer.

“I deeply appreciate the support you've provided throughout this project. It's clear why you came highly recommended by my colleague. Your team was exceptional, maintaining high morale throughout. Reflecting on our experience, I agree that considering temporary gas mainline valves, as you suggested, would be wise for future endeavors. Working alongside you and your team has been a pleasure, and your expertise was indispensable in completing the project successfully.” ~ Happy Client

As an N2 Solutions Company, PFS is dedicated to providing top-notch personnel, cutting-edge equipment, and efficient pigging systems to meet all your nitrogen-propelled pigging needs, regardless of size or complexity.

Whether it's offline mechanical cleaning, decommissioning, de-inventory, smart pigging, gauge plate runs, inerting, purging, or abandonment, we have the expertise and experience to handle it all.

Our comprehensive services include:

Project planning

Pig selection

Engineering calculations

Pig tracking

Want a copy of this case study? Click the download button now to receive a .PDF copy of our article.

Ready to kick off your next project? Request a quote today and get started today!

%20(3).png?width=180&height=90&name=N2%20-(300%20x%20150)%20(3).png) N2 Solutions strengthens their position as a nitrogen services leader with the acquisition of PFS Nitrogen Services, expanding its locations and product offerings. With pump trucks, nitrogen transports, pipeline chemical solutions, pig tracking, and pipe freeze technology, N2 delivers cost-effective solutions to energy, industrial, chemical, and pipeline clients. Together, N2 Solutions and PFS set a new standard of excellence in nitrogen solutions for their customers

N2 Solutions strengthens their position as a nitrogen services leader with the acquisition of PFS Nitrogen Services, expanding its locations and product offerings. With pump trucks, nitrogen transports, pipeline chemical solutions, pig tracking, and pipe freeze technology, N2 delivers cost-effective solutions to energy, industrial, chemical, and pipeline clients. Together, N2 Solutions and PFS set a new standard of excellence in nitrogen solutions for their customers

PFS Nitrogen Services, sister company of the industry leading N2 Solutions Company, is renowned for its expertise in nitrogen-propelled pigging...

PFS Nitrogen Services, the sister company of N2 Solutions, specializes in nitrogen-propelled pigging and pipe freeze isolations. This case...

Experience the unparalleled expertise of N2 Solutions, a premier provider of nitrogen services, as we present a testament to our proficiency in...