In the pipeline industry, maintaining the cleanliness and integrity of pipelines is crucial for ensuring safe and efficient operations. One of the key methods used to achieve this is pigging, a process that involves sending devices known as "pigs" through pipelines to clean, inspect, and maintain them. Whether it's removing debris or conducting in-line inspections, pigging plays an essential role in keeping pipelines operating at their best.

In this blog, we'll explore the basics of pigging, its types, and the critical role of nitrogen in pipeline maintenance, highlighting how these services can enhance pipeline efficiency and safety.

-

What is Pigging and How Does It Work?

-

Types of Smart Pigs

-

Why Use Nitrogen in Pipeline Maintenance?

-

How Does Pigging Enhance Pipeline Efficiency and Safety?

-

The Benefits of Combining Pigging with Nitrogen Services

-

What Industries Benefit Most from Pigging and Nitrogen Services?

What is Pigging and How Does It Work?

The pipeline industry has long relied on scrubbing and scraping devices, known as "pigs," to clean the interior of their piping systems. These pigs help reduce the build-up of waxes and other contaminants along the pipe's interior, ensuring efficient flow and reducing the risk of corrosion or blockages. The name "pig" originated from early devices made of straw bales wrapped in barbed wire or leather, which made a squealing noise as they moved through the pipes, reminiscent of a pig's squeal.

Pigging involves the insertion of a pig into the pipeline at a location such as a valve or pump station. The pig is propelled through the pipeline by the flow of the product or by another medium, such as gas or liquid. As it travels through the pipeline, the pig scrubs, scrapes, and removes debris from the pipe's interior, enhancing pipeline efficiency and safety.

In addition to these traditional cleaning pigs, the industry has developed sophisticated in-line inspection (ILI) tools, often called "smart pigs." These tools travel through the pipeline like cleaning pigs, but they are equipped with sensors and electronics to measure and record irregularities such as corrosion, cracks, deformations, and other defects in the pipeline. Smart pigs are inserted and retrieved at specially designed locations along the pipeline, where the recorded data is analyzed to assess the pipeline's condition.

Types of Smart Pigs

Magnetic Flux Tools:

- Magnetic Flux Leakage (MFL) Tool: This tool detects and measures metal loss (e.g., corrosion or gouges) using a temporarily applied magnetic field. As the tool moves through the pipe, it induces a magnetic flux in the pipe wall. Anomalies in the pipe, such as metal loss, cause a change in the magnetic flux distribution, which is detected and measured by sensors onboard the tool.

- Transverse MFL/Transverse Flux Inspection (TFI) Tool: Similar to the MFL tool but with a magnetic field oriented circumferentially around the pipe. This tool is handy for detecting longitudinally oriented corrosion and seam-related defects.

Ultrasonic Tools:

- Compression Wave Ultrasonic Testing (UT) Tool: Using ultrasonic signals, pipe wall thickness and metal loss are measured. The tool emits ultrasonic waves perpendicular to the pipe surface, and by analyzing the echo from both internal and external surfaces, it determines the wall thickness.

- Shear Wave Ultrasonic Testing (C-UT) Tool: Detects longitudinal cracks, weld defects, and crack-like defects using shear waves generated by the angular transmission of ultrasonic pulses through a liquid coupling medium.

Geometry Tools:

These tools use mechanical arms or electro-mechanical means to measure the pipe bore, identifying dents, deformations, and other changes in the pipe's geometry. They can also detect changes in girth welds, wall thickness, and bends in the pipeline.

Why Use Nitrogen in Pipeline Maintenance?

Nitrogen plays a critical role in ensuring pipelines' integrity, efficiency, and safety during maintenance activities. As an N2 Solutions company, we provide top-notch personnel, cutting-edge equipment, and efficient pigging systems to meet all your nitrogen-propelled pigging needs. Here’s why nitrogen is so essential:

- Purging & Inerting Pipelines: Nitrogen, an inert gas, does not react with other substances, making it ideal for purging pipelines. This process prevents oxidation, corrosion, and potentially explosive reactions during maintenance or repair activities. By displacing oxygen and other reactive gases, nitrogen creates a stable, non-reactive environment within the pipeline, which is crucial for safe operations.

- Safety: Safety is a top priority in pipeline maintenance, and nitrogen significantly enhances it. When used to purge pipelines, nitrogen displaces oxygen and flammable gases, reducing the risk of explosions or fires. This is especially critical for pipelines subject to Pipeline Integrity Management in High Consequence Areas (195.452), which is regulated by the Pipeline and Hazardous Materials Safety Administration (PHMSA) and the U.S. Department of Transportation (DOT). These regulations mandate stringent safety measures to protect pipelines in areas where a failure could have serious consequences. The inert atmosphere created by nitrogen ensures that the internal environment of the pipeline remains non-combustible, safeguarding both the pipeline and personnel.

- Pipeline Maintenance: Nitrogen is essential in various pipeline maintenance activities, including chemical cleaning and the running of In-Line Inspection (ILI) or smart tools. After hydrostatic testing or during routine maintenance, nitrogen is used to dry the pipeline, preventing moisture accumulation, which can lead to corrosion. Additionally, nitrogen helps preserve the pipeline during periods of inactivity by maintaining a dry, oxygen-free environment, thereby extending the pipeline's lifespan and reducing the frequency and severity of maintenance needs.

- Decommissioning of Pipelines: Nitrogen plays a vital role in decommissioning pipelines. This process involves cleaning, hydrostatic testing, repairs, and ongoing maintenance to ensure the pipeline is safely and effectively removed from service. Drying and Preservation are critical during decommissioning—after hydrostatic testing or other maintenance activities, nitrogen is used to dry the pipeline, preventing moisture accumulation that could lead to corrosion. Furthermore, nitrogen helps preserve the pipeline during inactivity by maintaining a dry, oxygen-free environment, protecting it from long-term degradation, and ensuring its integrity even when it is out of service.

By incorporating nitrogen into these critical aspects of pipeline operations, N2 Solutions ensures that pipelines remain safe, efficient, and well-maintained throughout their lifecycle, from active use to decommissioning.

How Does Pigging Enhance Pipeline Efficiency and Safety?

Pigging plays a critical role in maintaining pipeline efficiency and safety by:

- Removing Debris and Build-Up: Regular pigging clears out debris, scale, and other deposits that can accumulate inside pipelines. This ensures smooth flow, reduces pressure drops, and prevents blockages.

- Preventing Corrosion: By removing corrosive agents such as water, chemical deposits, and other contaminants, pigging helps prevent internal corrosion, extending the pipeline's lifespan.

- Ensuring Integrity: Inspection pigs equipped with sensors can detect anomalies, corrosion, and other integrity issues, allowing for early detection and repair before they become critical.

- Reducing Downtime: By keeping pipelines clean and well-maintained, pigging minimizes the need for unscheduled shutdowns, ensuring consistent operation and reducing maintenance costs.

The Benefits of Combining Pigging with Nitrogen Services

Combining pigging with nitrogen services offers enhanced benefits in pipeline maintenance:

- Comprehensive Cleaning: Nitrogen can propel the pig through the pipeline, ensuring the cleaning process is thorough and complete, especially in pipelines transporting sensitive or hazardous materials.

- Safety Enhancement: The inert nature of nitrogen adds an extra layer of safety during pigging operations by displacing oxygen and reducing the risk of fire or explosion.

- Moisture Removal: Nitrogen can dry the pipeline after pigging, removing any residual moisture left behind. This helps prevent corrosion and prepares the pipeline for the next operation phase.

- Preservation: For pipelines that will be idle for a period, nitrogen can maintain an inert atmosphere, preserving the pipeline's integrity until it is ready to be put back into service.

What Industries Benefit Most from Pigging and Nitrogen Services?

Several industries benefit significantly from pigging and nitrogen services, including:

- Oil and Gas: Pigging and nitrogen services are essential for maintaining pipelines transporting crude oil, natural gas, and refined products. These services help ensure the pipelines' efficiency, safety, and integrity, preventing corrosion, blockages, and potential failures that could lead to environmental hazards.

- Petrochemical: In the petrochemical industry, pigging and nitrogen maintain pipelines that carry chemicals and other products. The use of these services prevents contamination and corrosion, which are critical for maintaining product quality and ensuring the safety of the pipelines and surrounding environments.

- Water and Wastewater: Pigging is vital for cleaning and maintaining water and wastewater pipelines. Regular pigging ensures water quality by preventing the buildup of contaminants and blockages, which can affect the efficiency of water distribution and treatment systems.

- CO2 Pipelines: CO2 pipelines, which are increasingly used for carbon capture, utilization, and storage (CCUS) projects, also benefit from pigging and nitrogen services. These pipelines require regular maintenance to prevent corrosion and ensure safe carbon dioxide transport. Nitrogen purging is particularly important in these pipelines to prevent the formation of corrosive acids and maintain the system's integrity.

By applying pigging and nitrogen services across these industries, operators can ensure that their pipelines operate efficiently, safely, and reliably, minimizing risks and maintaining the highest performance standards.

N2 Solutions: Revolutionizing Pipeline Pigging

Pigging and nitrogen services are vital components of pipeline maintenance, offering a comprehensive approach to ensuring pipeline safety, efficiency, and longevity. Whether used separately or in combination, these services help maintain the integrity of pipelines across various industries, from oil and gas to water and wastewater systems.

At N2 Solutions, our team specializes in pigging and nitrogen services, providing expert personnel and state-of-the-art equipment to meet your maintenance needs. Let us help you with your next project—partner with N2 Solutions for reliable and efficient pipeline solutions. Contact us today!

About N2 Solutions

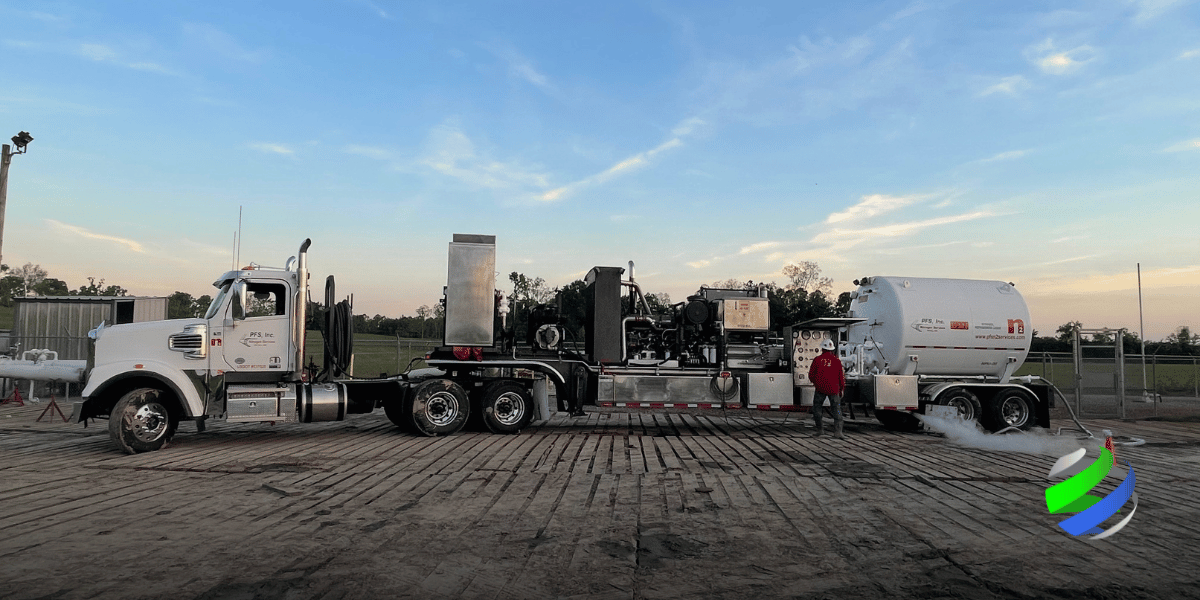

%20(3).png?width=180&height=90&name=N2%20-(300%20x%20150)%20(3).png) N2 Solutions strengthens their position as a nitrogen services leader with the acquisition of PFS Nitrogen Services, expanding its locations and product offerings. With pump trucks, nitrogen transports, pipeline chemical solutions, pig tracking, ILI tool runs, and pipe freeze technology, N2 delivers cost-effective solutions to energy, industrial (LNG), chemical, and pipeline clients. Together, N2 Solutions and PFS set a new standard of excellence in nitrogen solutions for their customers.

N2 Solutions strengthens their position as a nitrogen services leader with the acquisition of PFS Nitrogen Services, expanding its locations and product offerings. With pump trucks, nitrogen transports, pipeline chemical solutions, pig tracking, ILI tool runs, and pipe freeze technology, N2 delivers cost-effective solutions to energy, industrial (LNG), chemical, and pipeline clients. Together, N2 Solutions and PFS set a new standard of excellence in nitrogen solutions for their customers.

N2 Solutions

:

Sep 13, 2024 3:49:00 PM

N2 Solutions

:

Sep 13, 2024 3:49:00 PM

%20(3).png?width=180&height=90&name=N2%20-(300%20x%20150)%20(3).png) N2 Solutions strengthens their position as a nitrogen services leader with the acquisition of PFS Nitrogen Services, expanding its locations and product offerings. With pump trucks, nitrogen transports, pipeline chemical solutions, pig tracking, ILI tool runs, and pipe freeze technology, N2 delivers cost-effective solutions to energy, industrial (LNG), chemical, and pipeline clients. Together, N2 Solutions and PFS set a new standard of excellence in nitrogen solutions for their customers.

N2 Solutions strengthens their position as a nitrogen services leader with the acquisition of PFS Nitrogen Services, expanding its locations and product offerings. With pump trucks, nitrogen transports, pipeline chemical solutions, pig tracking, ILI tool runs, and pipe freeze technology, N2 delivers cost-effective solutions to energy, industrial (LNG), chemical, and pipeline clients. Together, N2 Solutions and PFS set a new standard of excellence in nitrogen solutions for their customers.