Revolutionizing Pipe Maintenance: N2 Solutions' Pipe Freezing Service

In the pipe maintenance industry, efficiency and precision are paramount. Leaks, disruptions, and repairs pose formidable hurdles, often...

2 min read

N2 Solutions

:

Dec 5, 2024 6:51:30 AM

N2 Solutions

:

Dec 5, 2024 6:51:30 AM

In the world of industrial maintenance and repair, versatility and efficiency are key. Freeze plugs, created through the process of pipe freezing, are an innovative solution that allows for safe isolation of systems without the need for draining or shutting down operations.

While often associated with pipelines, freeze plugs are a game-changing tool used in a variety of industries, from hospitals and HVAC systems to breweries and marine applications. This blog explores the many uses of freeze plugs, showcasing their adaptability and why they’re an essential tool for industries aiming to minimize downtime and maximize performance.

Freeze plugs are a cutting-edge solution that leverage the process of pipe freezing to create temporary ice blockages within pipes or systems. By using liquid nitrogen to freeze a specific section, a solid and dependable barrier is formed, enabling maintenance, repairs, or leak detection without interrupting the entire system's operations.

Freeze plugs have broad applications across various industries. Their versatility allows them to be used wherever a freezable liquid is present, offering an efficient way to address isolation challenges, prevent downtime, and streamline repairs. From large-scale HVAC systems to municipal infrastructures, freeze plugs provide a reliable solution for industries seeking innovative approaches to system management.

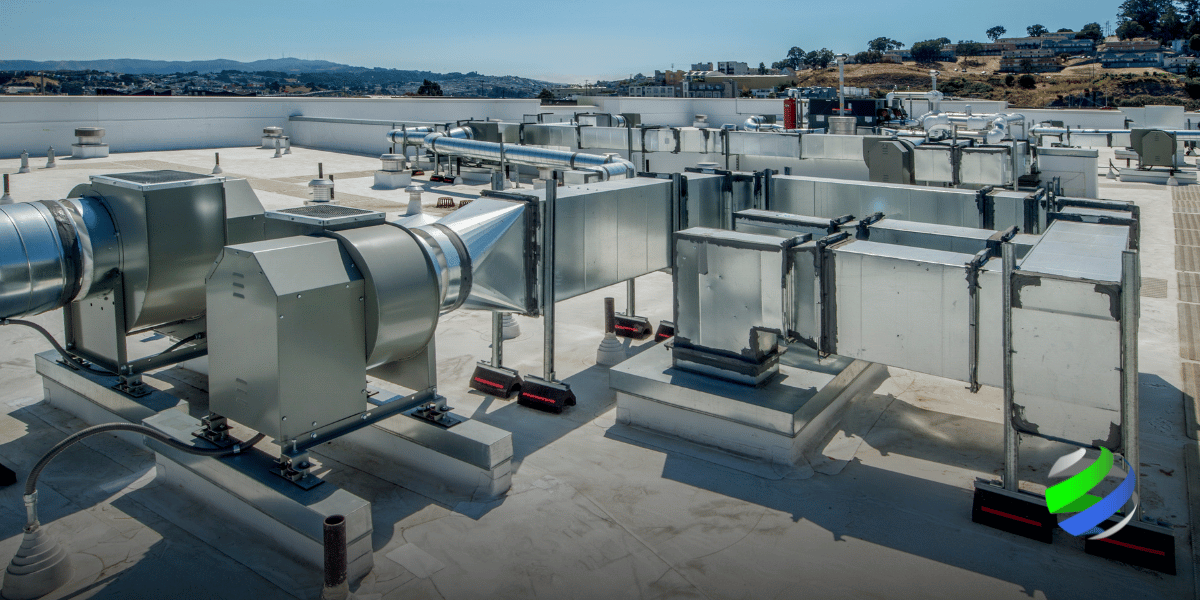

Large facilities, such as stadiums, hospitals, and corporate buildings, often house complex HVAC systems with chillers, water towers, and extensive piping. Freeze plugs allow technicians to isolate specific sections of these systems for upgrades, repairs, or emergency leak control without shutting down the entire operation.

For example, in facilities like the Superdome or large hospitals, downtime can lead to significant inconvenience or even life-threatening situations. Freeze plugs provide an effective alternative, ensuring that only the necessary areas are impacted during maintenance or repair projects.

The versatility of freeze plugs extends across multiple markets, including:

City water systems and sewage networks can use freeze plugs to isolate sections for repair or inspection without cutting off service to entire communities.

In medical facilities, maintaining operational HVAC and plumbing systems is crucial. Freeze plugs minimize disruptions, ensuring patient care is uninterrupted.

As mentioned earlier, chillers, water towers, and other HVAC components in large facilities benefit significantly from pipe freezing techniques.

Breweries use freeze plugs to isolate fermentation tanks or coolant systems for maintenance. Similarly, paper mills can apply pipe freezing to manage chemical flows and prevent production downtime.

Ships and marine vessels often require precise isolation of pipelines or systems for maintenance while at sea. Freeze plugs offer a dependable solution in such environments.

Although commonly associated with pipelines, freeze plugs have far more applications. They can freeze any freezable liquid, making them suitable for numerous industries and scenarios. Whether isolating a single section of pipe in a brewery or managing a water tower in an industrial park, freeze plugs deliver reliable results.

Moreover, freeze plugs support proactive planning. Businesses can develop new markets and expand their services using freeze plug technology, demonstrating adaptability and innovation.

Freeze plugs are a game-changing solution for isolation, maintenance, and repair needs across a wide range of industries. From municipalities and hospitals to breweries and marine applications, the possibilities are vast.

At N2 Solutions, we specialize in pipe freezing and freeze plug services tailored to your industry’s needs. No matter the industry, we’re committed to helping customers discover new ways to use freeze plugs to minimize downtime and maximize efficiency. Contact N2 Solutions today to request a quote for your next project!

%20(3).png?width=180&height=90&name=N2%20-(300%20x%20150)%20(3).png) N2 Solutions strengthens their position as a nitrogen services leader with the acquisition of PFS Nitrogen Services, expanding its locations and product offerings. With pump trucks, nitrogen transports, pipeline chemical solutions, pig tracking, and pipe freeze technology, N2 delivers cost-effective solutions to energy, industrial, chemical, and pipeline clients. Together, N2 Solutions and PFS set a new standard of excellence in nitrogen solutions for their customers.

N2 Solutions strengthens their position as a nitrogen services leader with the acquisition of PFS Nitrogen Services, expanding its locations and product offerings. With pump trucks, nitrogen transports, pipeline chemical solutions, pig tracking, and pipe freeze technology, N2 delivers cost-effective solutions to energy, industrial, chemical, and pipeline clients. Together, N2 Solutions and PFS set a new standard of excellence in nitrogen solutions for their customers.

In the pipe maintenance industry, efficiency and precision are paramount. Leaks, disruptions, and repairs pose formidable hurdles, often...

Nitrogen (N2) is one of the most versatile gases in industrial applications, offering unique properties that make it indispensable in a wide...

PFS Nitrogen Services, a sister company of N2 Solutions, specializes in nitrogen-propelled pigging and pipe freeze isolations. This case study...