What Is Pigging? A Comprehensive Guide to Pipeline Cleaning and Safety

In the pipeline industry, maintaining the cleanliness and integrity of pipelines is crucial for ensuring safe and efficient operations. One of the...

N2 Solutions is proud to partner with Propipe North America, a leading provider of pipeline pigging solutions. This partnership strengthens our ability to support pipeline integrity and maintenance with cutting-edge technology and expertise. In this article, we’ll introduce Propipe North America, explore their role in the industry, and discuss how their innovative pigging solutions enhance pipeline operations.

Pipeline pigging is an essential process in pipeline maintenance, cleaning, and monitoring. Traditionally, tracking pigs, or devices used to clean and inspect pipelines, involved a team of people leap frogging along the pipeline. This method could be hazardous, especially during nighttime or in remote locations. However, with the advent of automated pig tracking, this process has become safer, more efficient, and more accurate. In this guide, we’ll explore how automated pig tracking works, its benefits, and the role Propipe plays in revolutionizing pipeline maintenance.

Automated pig tracking is an advanced method for monitoring the passage of pigs through pipelines without the need for on-site personnel to listen for them manually. In traditional pigging operations, personnel were stationed at various points along the pipeline with geo-phones and receivers to track the pigs' location. This required constant listening and physical tracking, a process that could be dangerous and labor-intensive, especially at night or in hazardous locations.

With automated pig tracking, the pigs can provide information that sends to the transmitters such as speed, pressures, bends in the pipeline, and the location of where the pig starts and stops. This communicates real-time data remotely to AGM’s connected to a cellular network, then uploaded to the cloud. This shift to automation eliminates the need for on-the-ground personnel and reduces the risks associated with manual tracking.

Propipe’s automated pig tracking system relies on MAG, ELF, Acoustic sensing and transmitters placed into the pigs themselves. These transmitters continuously send data to AGMs, which record the pig’s passage and location with timestamped accuracy. This system aggregates data in real time, providing operators with comprehensive reports about the pig’s passage, speed, and location, along with other relevant pipeline data such as accelerometers and gyroscopes and as options pressure and temperature.

The system can also be supplemented by data from Inline Inspection (ILI) tools, creating a more detailed understanding of the pipeline’s condition. By utilizing cloud storage, this data is processed instantly, enabling operators to access a wealth of information that is automatically collected. This makes data collection more efficient and reliable, streamlining operations and enhancing safety.

Enhanced Safety: Traditional pig tracking required crew members to be positioned along the pipeline, often in dangerous conditions. Accidents were not uncommon, especially in low-visibility or high-risk areas. Automated pig tracking removes the need for personnel to be physically present, drastically reducing the risk of accidents.

Cost Efficiency: By automating the tracking process, the need for a large on-site team is eliminated, reducing labor costs. Additionally, data is processed remotely, eliminating the time-consuming process of manually downloading data from other AGMs.

Real-Time Data & Reporting: With automated tracking, data is collected in real time and can be accessed instantaneously through cloud-based systems. This includes live geophone audio waveforms, pig speed, and other critical metrics. Operators can monitor pipeline health in real time and make informed decisions based on up-to-the-minute information.

Accuracy and Reliability: One of the critical challenges with traditional pig tracking was safety and accuracy of data. Automated systems, like the ones offered by Propipe, are designed to minimize these errors, ensuring that pig tracking is as accurate as possible.

Scalability and Efficiency: The use of intelligent transmitters allows for a wide range of data to be collected, including vibrational and pressure data, and location that was previously hard to track. This data helps operators gain a more complete understanding of pipeline performance, which is essential for predictive maintenance and future optimization.

By incorporating nitrogen into these critical aspects of pipeline operations, N2 Solutions ensures that pipelines remain safe, efficient, and well-maintained throughout their lifecycle, from active use to decommissioning.

Propipe stands at the forefront of automated pig tracking, offering both transmitters and receivers designed to collect and transmit crucial pipeline data. The company's intelligent transmitters are equipped to log vibrational data, pressure data, and more, helping operators gain insight into pipeline conditions without the need for manual data extraction. Their system also includes the latest magnetic sensing technology, ensuring accurate detection and minimal false positives.

Propipe's system is built to the latest industry standards, allowing for remote tracking, manual tracking, locating stuck pigs, land use, marsh use, and offshore use to be done from anywhere, at any time. Whether you're managing a single pipeline or multiple systems, Propipe’s solutions provide the tools needed to streamline pig tracking, enhance safety, and improve data accuracy.

Automated pig tracking represents a significant leap forward in pipeline maintenance and monitoring. By leveraging Propipe’s advanced tracking technology, pipeline operators can ensure safer, more efficient, and more reliable operations. With the ability to track pigs remotely and in real time from anywhere in the world, reducing human error, and enhance safety, automated pig tracking is the future of pipeline monitoring and maintenance.

Pigging and nitrogen services are vital components of pipeline maintenance, offering a comprehensive approach to ensuring pipeline safety, efficiency, and longevity. Whether used separately or in combination, these services help maintain the integrity of pipelines across various industries, from oil and gas to water and wastewater systems.

At N2 Solutions, our team specializes in pigging and nitrogen services, providing expert personnel and state-of-the-art equipment to meet your maintenance needs. Let us help you with your next project—partner with N2 Solutions for reliable and efficient pipeline solutions. Contact us today!

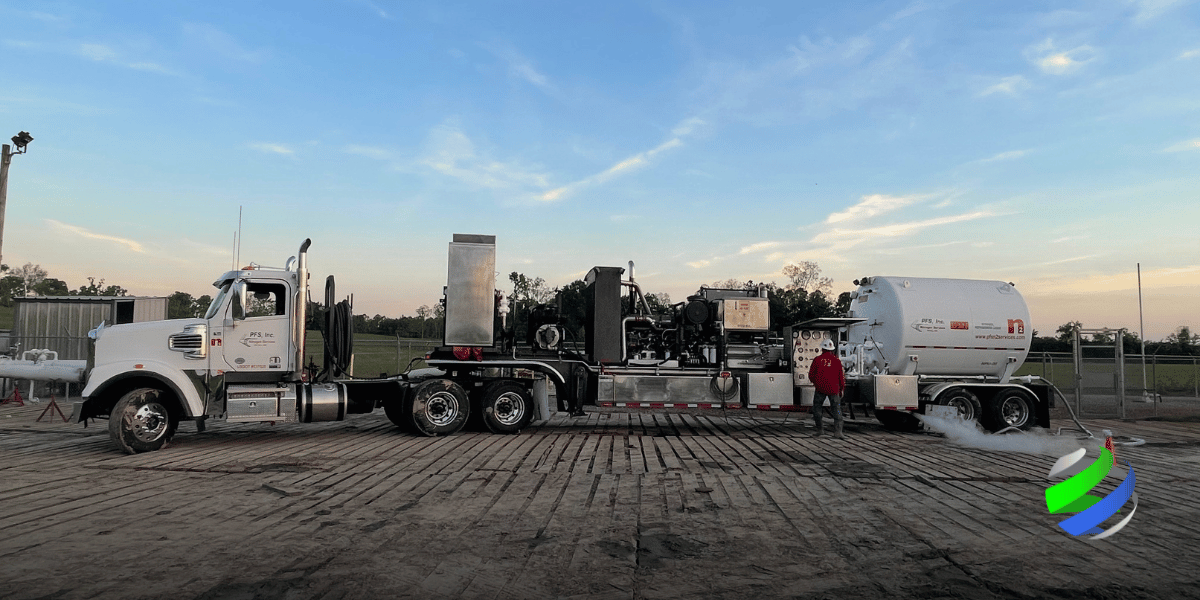

%20(3).png?width=180&height=90&name=N2%20-(300%20x%20150)%20(3).png) N2 Solutions strengthens their position as a nitrogen services leader with the acquisition of PFS Nitrogen Services, expanding its locations and product offerings. With pump trucks, nitrogen transports, pipeline chemical solutions, pig tracking, ILI tool runs, and pipe freeze technology, N2 delivers cost-effective solutions to energy, industrial (LNG), chemical, and pipeline clients. Together, N2 Solutions and PFS set a new standard of excellence in nitrogen solutions for their customers.

N2 Solutions strengthens their position as a nitrogen services leader with the acquisition of PFS Nitrogen Services, expanding its locations and product offerings. With pump trucks, nitrogen transports, pipeline chemical solutions, pig tracking, ILI tool runs, and pipe freeze technology, N2 delivers cost-effective solutions to energy, industrial (LNG), chemical, and pipeline clients. Together, N2 Solutions and PFS set a new standard of excellence in nitrogen solutions for their customers.

In the pipeline industry, maintaining the cleanliness and integrity of pipelines is crucial for ensuring safe and efficient operations. One of the...

Experience the unparalleled expertise of N2 Solutions, a premier provider of nitrogen services, as we present a testament to our proficiency in...

Safety is at the core of LNG operations, and N2 Solutions is committed to ensuring the highest standards through innovative nitrogen services and...